R&D + innovation

Prototype, test, and launch with confidence

Pelican’s innovation center pairs material science with pilot equipment to de-risk launches and accelerate approvals.

Co-creation toolkit

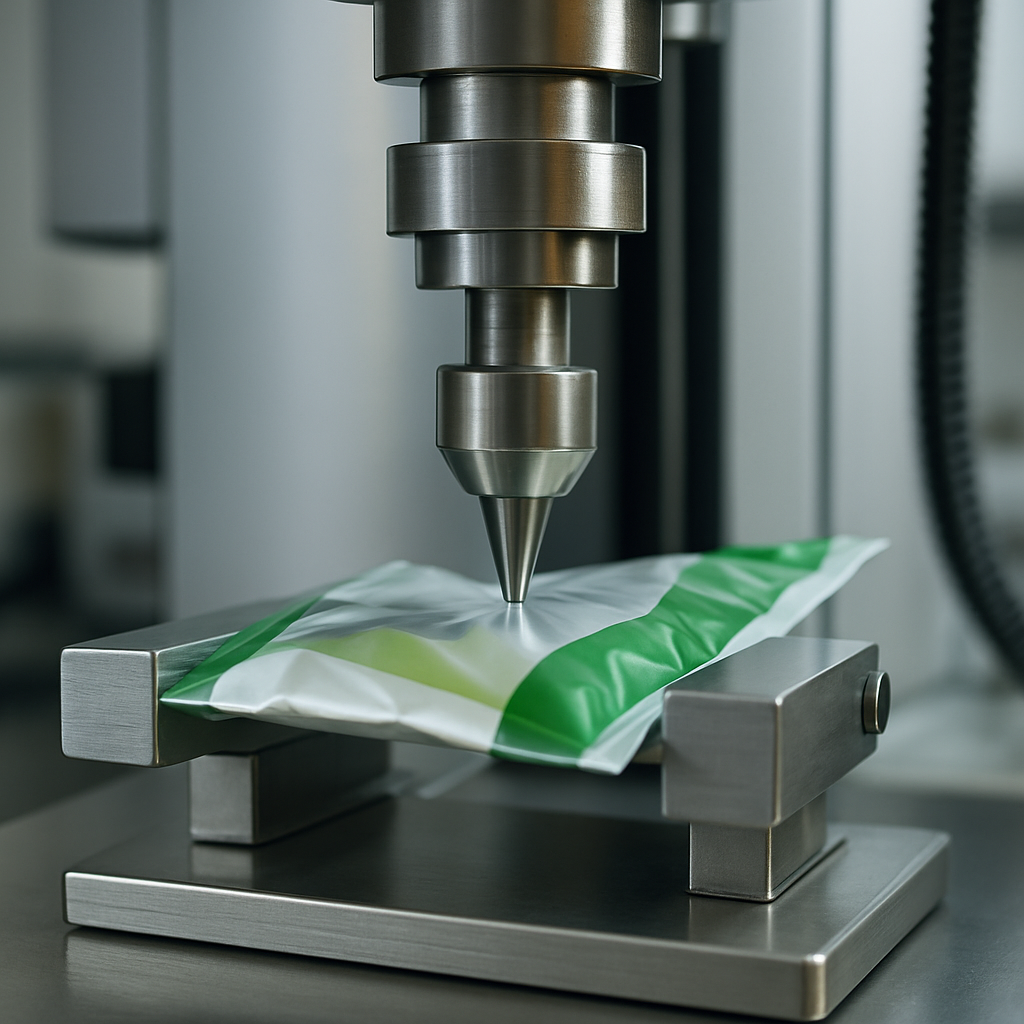

- Barrier, COF, seal, and burst testing

- Pilot pouching with live graphics

- Environmental aging and shelf-life modeling

Development path

From idea to production with clear gates and data

We map every project with defined checkpoints so stakeholders can make decisions with confidence.

Material design

Barrier targets, seal needs, sustainability goals, and regulatory considerations defined up front.

- Application and channel assessment

- Monomaterial and PCR options

- Heat-seal window planning

Pilot & validation

Rapid prototypes to prove form, function, and graphics before committing to full runs.

- Pouches and webs with production inks

- Seal, burst, and peel testing

- COF and machinability checks

Launch & scale

Production trials with inline inspection, lot traceability, and documentation ready for audits.

- Roll maps and COAs

- Change control and approvals

- Post-launch optimization loops