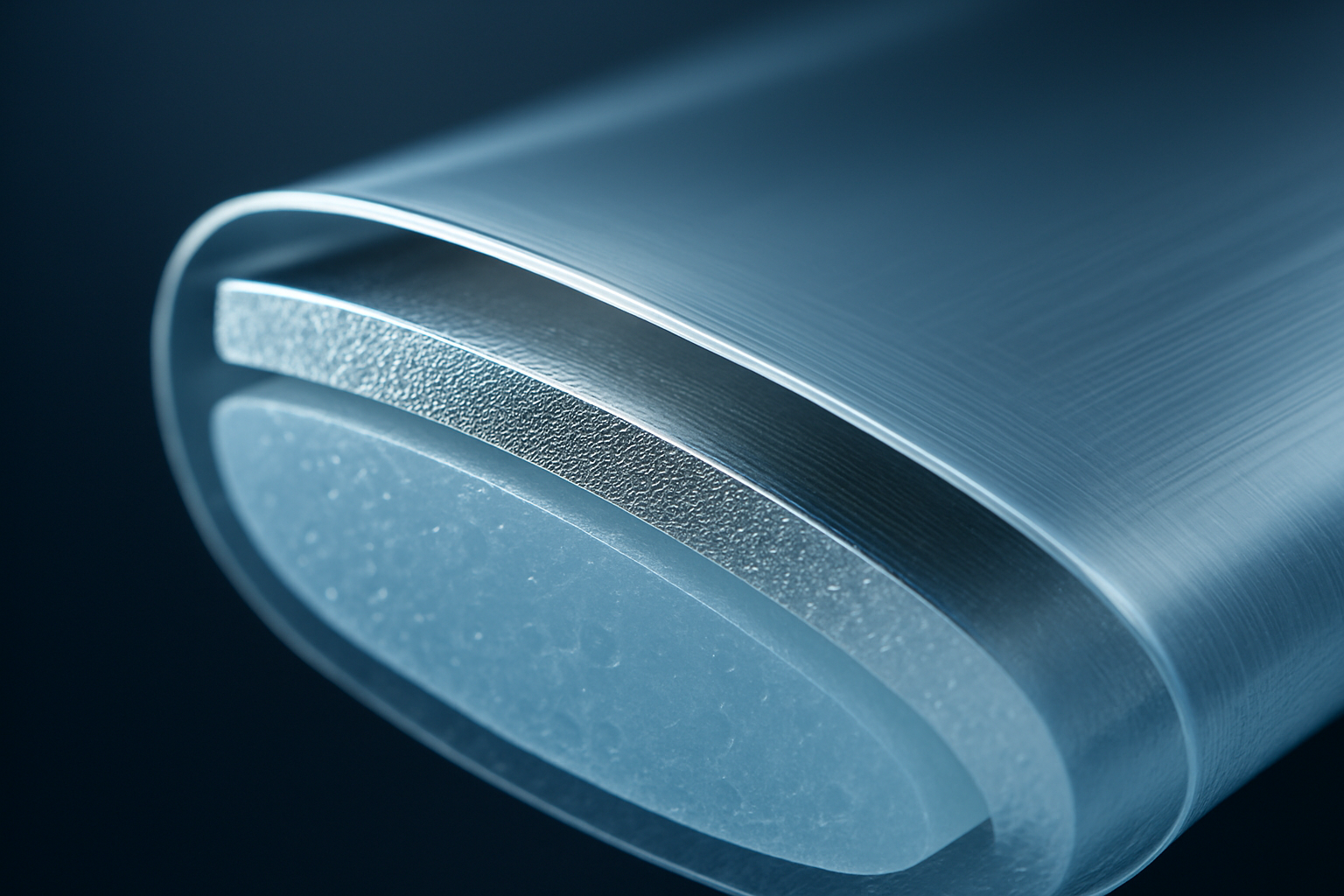

Lamination & bonding

Multi-layer barrier structures engineered for your product

We pair paper, films, and foil with the right adhesive systems to deliver oxygen, moisture, light, and aroma protection without compromising conversion.

What we optimize

- OTR/MVTR targets for food and medical sterility

- Puncture and burst strength for e-commerce and industrial

- Peelable and weld seal combinations for precise opening forces

Process controls

Adhesive control, registration, and barrier performance

Every laminate is verified for structure, coating weight, and seal performance with data you can use to qualify and scale.

Solventless & solvent-based

Choose the system that matches your barrier and regulatory needs without compromising bond strength.

- Paper/film/foil hybrid builds

- Controlled coat weight windows

- Low-migration adhesive options

Registration and flatness

Accurate lay-down and web control prevent curl and maintain print-to-laminate alignment.

- Automatic tension and temperature control

- Inline inspection and roll mapping

- Certificates of analysis per lot

Seal window validation

Peelable and weld seal builds tested for your equipment, fill conditions, and opening force targets.

- Peel force profiling

- Seal-through-contaminant testing

- Hot-fill and retort validation