Engineered for Protection. Designed for Performance.

Pelican Holdco LLC delivers advanced coated and laminated films that safeguard product integrity, elevate shelf appeal, and run flawlessly on high-speed lines.

- Multi-layer barrier structures tuned for oxygen, moisture, light, and aroma control.

- ISO-driven quality systems with inline inspection and lot traceability.

- Co-development pathways: prototypes, rapid trials, and scale-up support.

Barrier stack expertise

- Paper | PET | PE | PP | foil hybrid structures

- Heat-seal, anti-fog, peelable, and weld seals

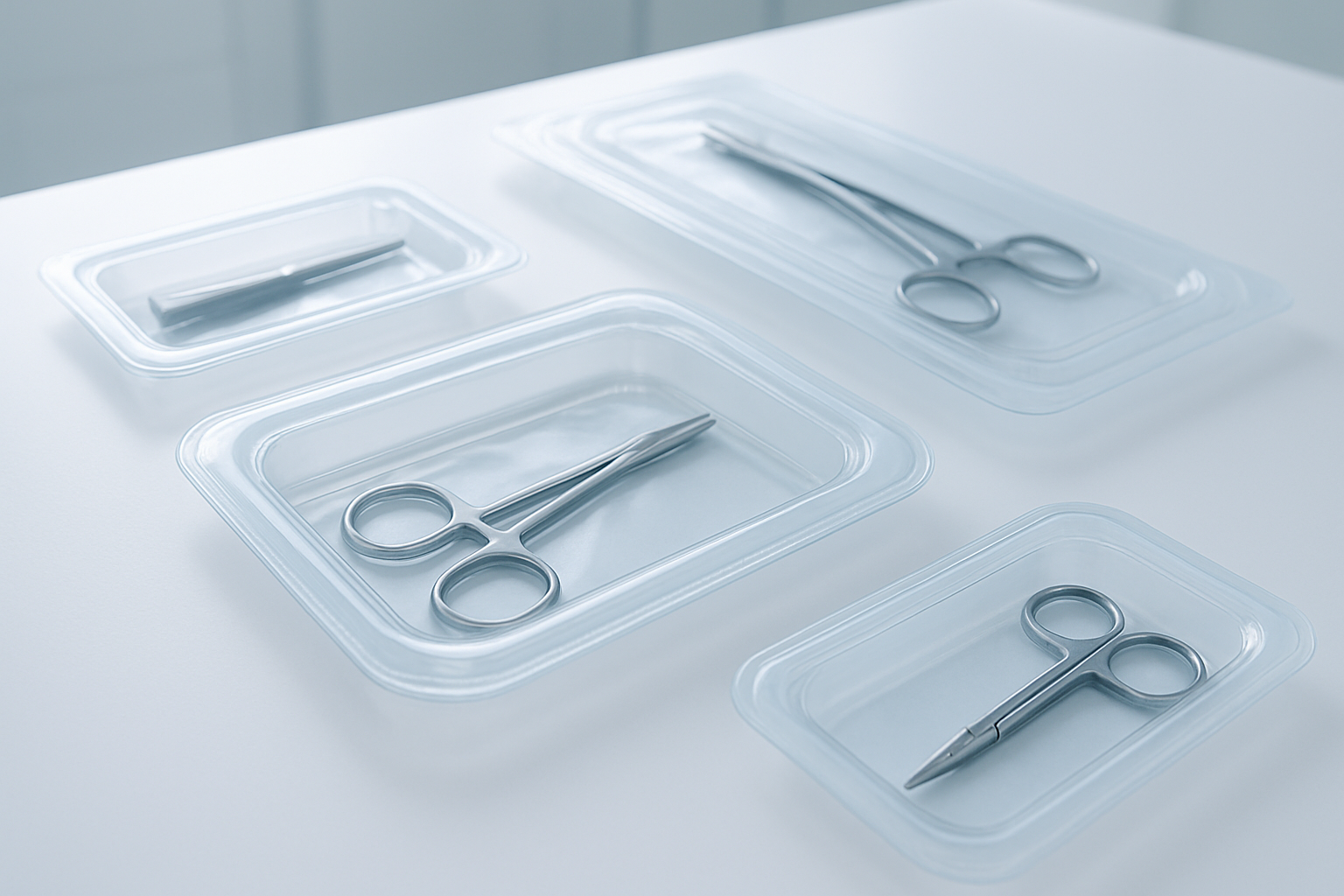

- Cleanroom-ready conversion for medical runs

Visibility across every step — lamination through R&D

A transparent production chain lets you validate barrier performance, graphics, and sustainability metrics before you scale.

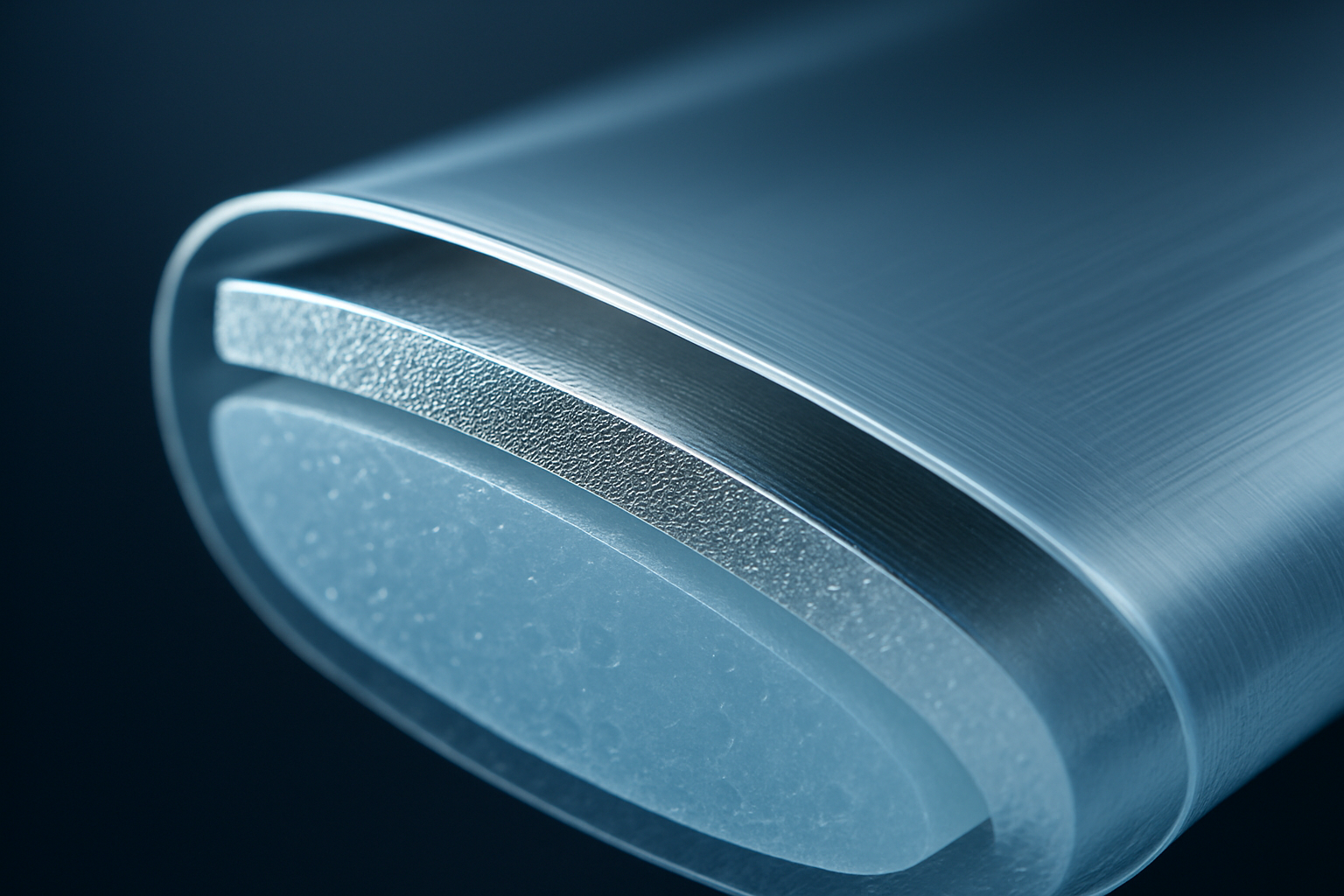

Lamination & Bonding

Multi-layer builds pairing paper, films, and foil for tailored barrier stacks.

Precision Coating

Functional coatings for heat-seal, anti-fog, and high-clarity windows.

Slitting & Rewinding

Tight tolerances for FFS, VFFS, and pouching lines with verified roll health.

High-Definition Printing

10-color flexo with GMI-compliant color management and repeatability.

R&D + Prototyping

Rapid trials, lab validation, and co-development with your technical team.

Controlled adhesive windows

Solventless/solvent-based adhesive systems with precise coat weight to lock in oxygen, moisture, and aroma performance while protecting paper feel or foil puncture resistance.

- Paper + PET + Foil + PE hybrid stacks

- Hot-fill and retort capable builds

- Validated peel/weld seal profiles

Function-first coatings

Extrusion and aqueous coatings deliver anti-fog clarity, seal-through-contaminant performance, and puncture resistance for e-commerce and refrigerated channels.

- Optically clear windows for fresh foods

- High COF control for line efficiency

- Monomaterial PE/PP recyclable tracks

Conversion-ready rolls

Edge quality and roll build integrity verified on every lot to prevent downtime on FFS, VFFS, and pouching lines.

- Inline defect detection and map logs

- Tight slit tolerances for medical webs

- Lot-level roll health documentation

Brand-perfect graphics

10-color HD flexo with extended gamut and GMI controls to keep brand color standards locked in across every run.

- Spot + process with precise ink densities

- Matte/gloss combo and tactile finishes

- Traceable color targets and approvals

Lab + pilot + scale

Barrier, seal, and aging tests validate performance before commercial runs. Pilot pouches accelerate market tests without tying up production time.

- Barrier, seal strength, burst, peel

- Environmental chamber aging studies

- Regulatory guidance for food/medical

Food, medical, and industrial performance without compromise

Purpose-built structures for critical shelf-life, sterility, and durability demands.

Food & Beverage

Barrier control for snacks, coffee, frozen, and ready-meal formats with retail-ready graphics.

Medical & Pharma

Sterile barrier systems with validated seal windows and cleanroom-ready conversion.

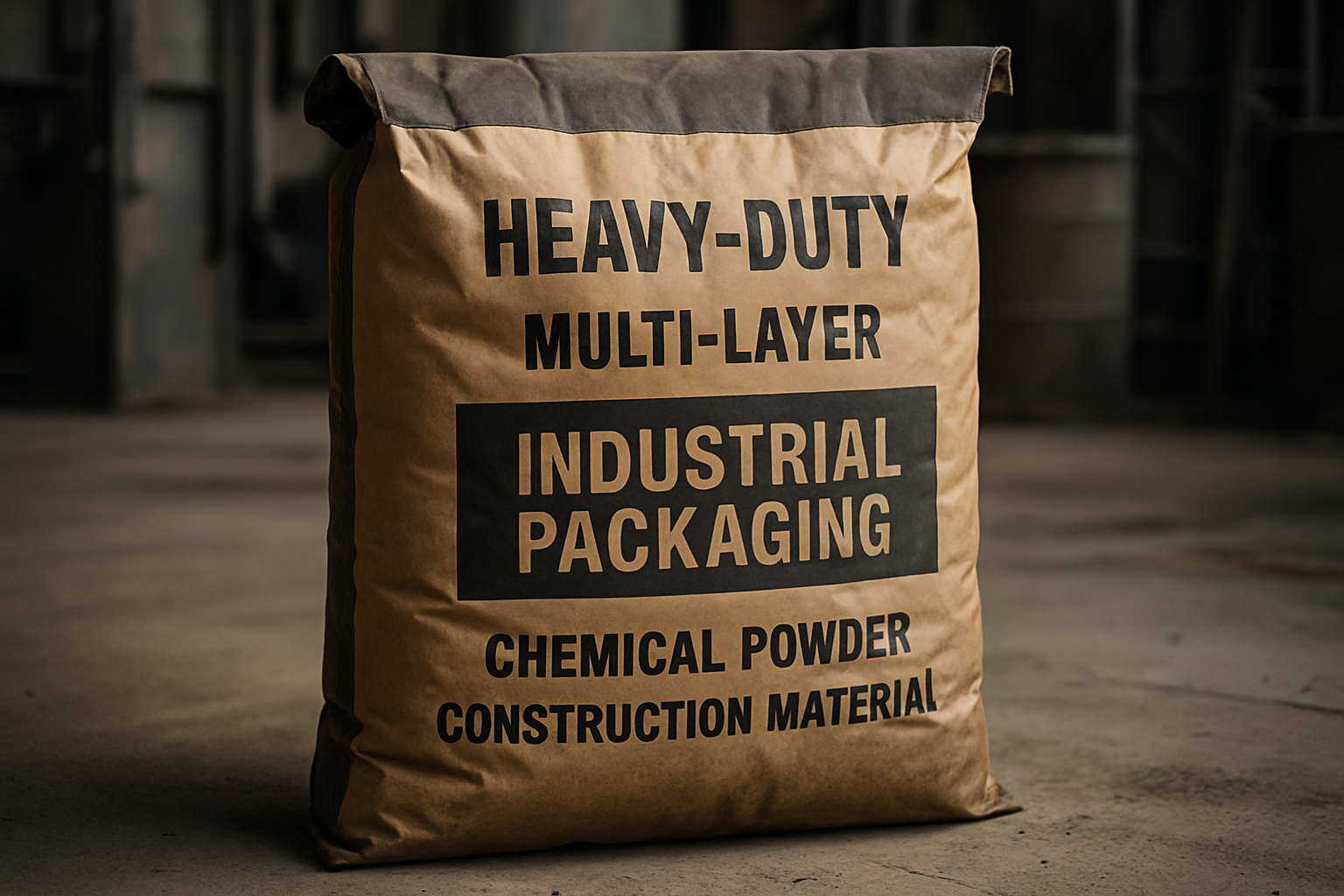

Industrial & Chemical

Durable, puncture-resistant laminates for construction, chemical, and e-commerce channels.

Data-backed progress on recyclability, PCR, and carbon

Transparent metrics to help you hit retailer scorecards and brand ESG commitments.

PCR integration

Post-consumer content in qualifying film families with ongoing trials to 50%.

Recyclable structures

PE/PP monomaterial paths aligned with store drop-off and How2Recycle® claims.

Operational efficiency

Energy per MSI reduced through heat recovery, LED retrofits, and optimized runs.

Material circularity

Scrap regrind, reuse, and certified downstream partners for remaining streams.

Plan, prove, certify.

Lifecycle data packages and test reports for your sustainability, regulatory, and retailer submissions.

Co-create the next generation of flexible packaging

Prototype, test, and validate with Pelican’s material scientists. From concept to pilot to production, we de-risk launches while meeting your barrier, brand, and sustainability targets.

Pilot-ready services

- Prototype pouch builds with live graphics

- Barrier, seal, and burst lab data packs

- Retail + e-commerce channel simulation